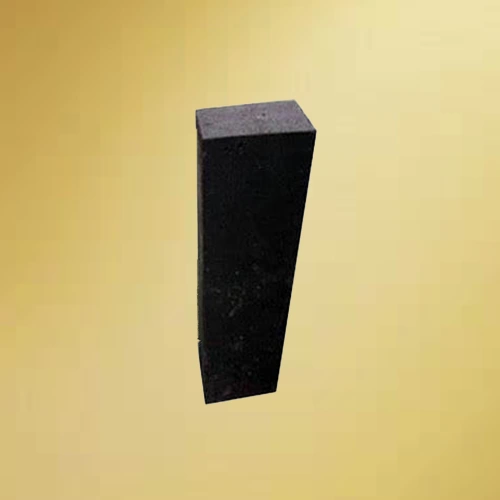

Cupola Bricks – High-Performance Heat Resistance for Metal Melting

Poonam Refratech’s Cupola Bricks are designed for cupola furnaces, providing exceptional durability, heat resistance, and thermal stability. These bricks ensure efficient metal melting, reducing heat loss and improving operational longevity in foundries and steel industries.

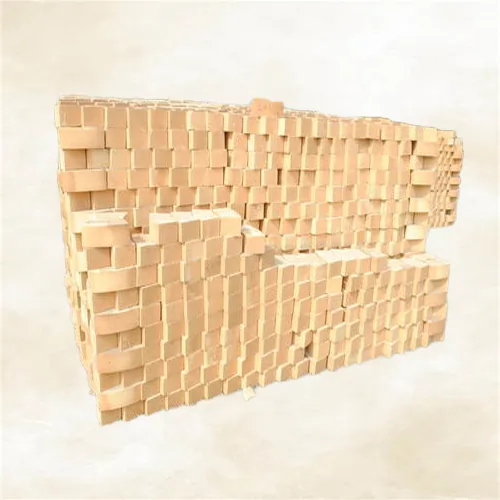

Specifications:

- Material Composition: High alumina and magnesite-based refractory blend.

- Maximum Heat Resistance: Up to 1,750°C, ideal for molten metal handling

- Density: Optimized for thermal insulation and energy efficiency

- Mechanical Strength: High durability against abrasion and slag attacks

- Chemical Stability: Resists corrosive gases and molten metal exposure

- Applications: Essential for cupola furnaces, steel casting, and metal foundries

Reliable Cupola Bricks for Efficient Metal Processing

Poonam Refratech’s Cupola Bricks ensure stable heat retention and structural integrity, making them the preferred choice for cupola furnace linings. Their high-performance thermal resistance enhances metal melting efficiency, ensuring cost-effective and smooth operations.

Usage & Applications:

- Iron & Steel Foundries: Provides uniform heat distribution for metal melting.

- Cupola Furnaces: Enhances thermal efficiency and reduces heat loss.

- Metal Casting Units: Ensures stable refractory lining for molten metal processing.

- Non-Ferrous Metal Industries: Maintains consistent temperature for high-quality casting.

- Industrial Kilns & Boilers: Used for thermal insulation in various high-heat applications.