In industries where extreme heat is a constant factor, fire bricks serve as a crucial component for thermal insulation and structural durability. These high-temperature resistant bricks are widely used in furnaces, kilns, boilers, and industrial ovens, offering exceptional heat retention, energy efficiency, and long-lasting performance.

At Poonam Refratech, we provide premium fire bricks designed to withstand intense heat, thermal shocks, and harsh industrial conditions, ensuring maximum efficiency and protection. Let’s explore their features, types, and applications.

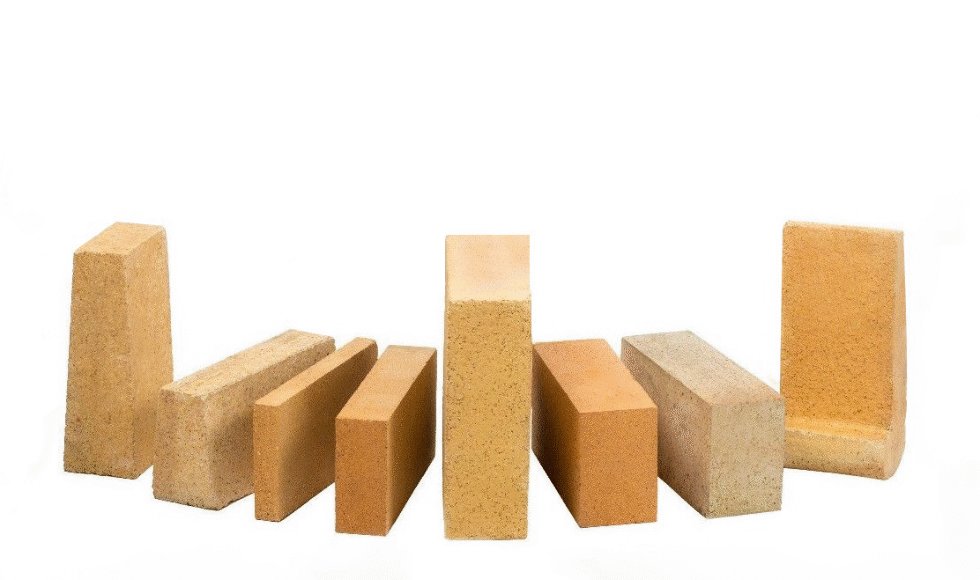

What Are Fire Bricks?

Fire bricks, also known as refractory bricks, are specialized heat-resistant bricks made from high-quality ceramic materials that can endure temperatures of up to 1,700°C without losing strength or integrity.

Key Features of Fire Bricks:

- High Heat Resistance – Ideal for use in extreme temperature environments.

- Thermal Insulation – Reduces heat loss, improving energy efficiency.

- Strong Durability – Resistant to cracks, erosion, and mechanical stress.

- Chemical Stability – Protects against exposure to molten metals, slag, and harsh gases.

- Low Porosity – Minimizes heat transfer for better insulation performance.

Types of Fire Bricks

Fire bricks come in different grades and compositions to match specific industrial needs:

- Low-Density Insulating Fire Bricks

Lightweight with excellent thermal insulation.

Used in back-up linings for furnaces and ovens

- High-Density Fire Bricks

Heavy-duty bricks with strong mechanical stability.

Suitable for direct flame and high-temperature applications.

- High Alumina Fire Bricks

Made from alumina-rich compositions for superior thermal resistance.

Commonly used in cement kilns, steel plants, and glass furnaces. - Acid-Resistant Fire Bricks

Designed for chemical processing units.

Protects against acidic environments and corrosive materials. - Special Magnesite Fire Bricks

Manufactured for extreme temperature industrial processes.

Used in steel furnaces and non-ferrous metal industries.

Applications of Fire Bricks

- Steel & Metallurgy Industry

Used in blast furnaces, ladles, and converters to contain extreme heat and molten metal. - Cement & Lime Production

Installed in kilns, preheaters, and calciners for efficient heat insulation. - Power Plants & Boilers

Optimizes fuel combustion efficiency, reducing heat loss and operational costs. - Petrochemical & Refineries

Provides protection in chemical reactors, fluidized beds, and gasifiers. - Glass & Ceramics Manufacturing

Used in melting furnaces and kilns for consistent temperature control.

Why Choose Poonam Refratech’s Fire Bricks?

At Poonam Refratech, we offer top-quality fire bricks engineered for industrial strength, durability, and performance.

Our Advantages:

- High-Temperature Stability – Withstands extreme heat conditions without deterioration.

- Superior Insulation – Reduces heat loss, improving energy efficiency.

- Long-Lasting Durability – Built to resist thermal shocks and mechanical wear.

- Customized Solutions – Available in different grades for various industrial applications.

Conclusion

Fire bricks are essential for industries that rely on high-temperature processes, ensuring structural integrity, energy efficiency, and long-term protection. With Poonam Refratech’s premium fire bricks, businesses can enjoy enhanced performance, safety, and reliability in their operations.

Looking for high-quality fire bricks?

Contact Poonam Refratech today to explore our expert-crafted refractory solutions for your industrial needs!